With all the focus on CO2 greenhouse gas emissions, NOx and SOx, it’s easy to think that mitigating these harmful gases is the core focus of exhaust after-treatment systems for superyachts. As IMO Tier III makes its presence felt, and with an increasing likelihood of expanded and additional Emission Control Areas (ECAs) encompassing traditional yachting hotspots in the future, it’s easy to forget there’s another side to exhaust treatment that is arguably just as important for the health of the crew, owner and guests as it is for the environment – so-called particulate matter, more easily identified as soot.

It’s something that exhaust treatment specialists Xeamos focus on in a new white paper written by its in-house engineering experts, and it’s critical to consider the impact that particulate matter has. At its most basic level, it’s about pristine luxury and being able to enjoy the beautiful anchorages and harbours yachts can visit – those noxious exhaust fumes that can drift across the aft beach at anchor and the film of carbon that can form on the crystal clear waters around a yacht are the result of particulate matter. And it’s not just about the onboard comfort and in-water enjoyment of guests, because particulate matter is particularly nasty when it comes to human health.

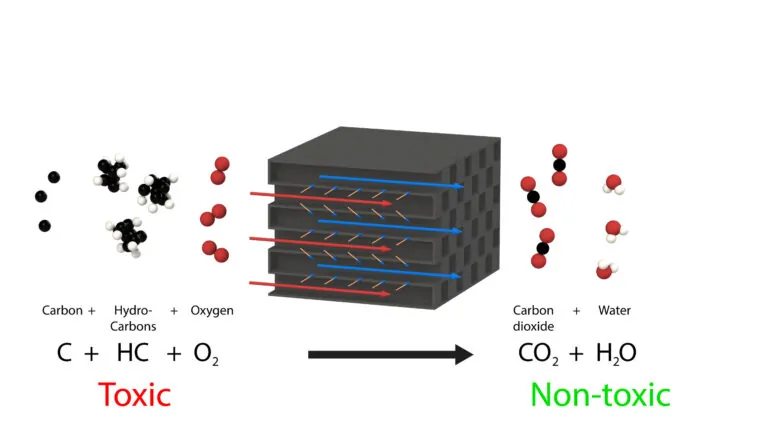

Particulates can be breathed in, penetrating the lungs, and smaller particulates can also then be absorbed into the bloodstream. This can potentially lead to cardiovascular and respiratory problems over the long term. Such particulates – comprising carbon, hydrocarbons and ash residue – are defined as PM10 or PM2.5, which means the size of the measured average particles is just 10 micrometres or 2.5 micrometres respectively, and it’s not difficult to understand the dangers that they can pose. For owners and guests, and especially for crew who are exposed day in and day out over the long term to engine exhaust fumes, it is, therefore, essential to ensure that exhaust treatment systems don’t just tackle harmful gases, but also are optimised to remove particulate matter from the exhaust flow.

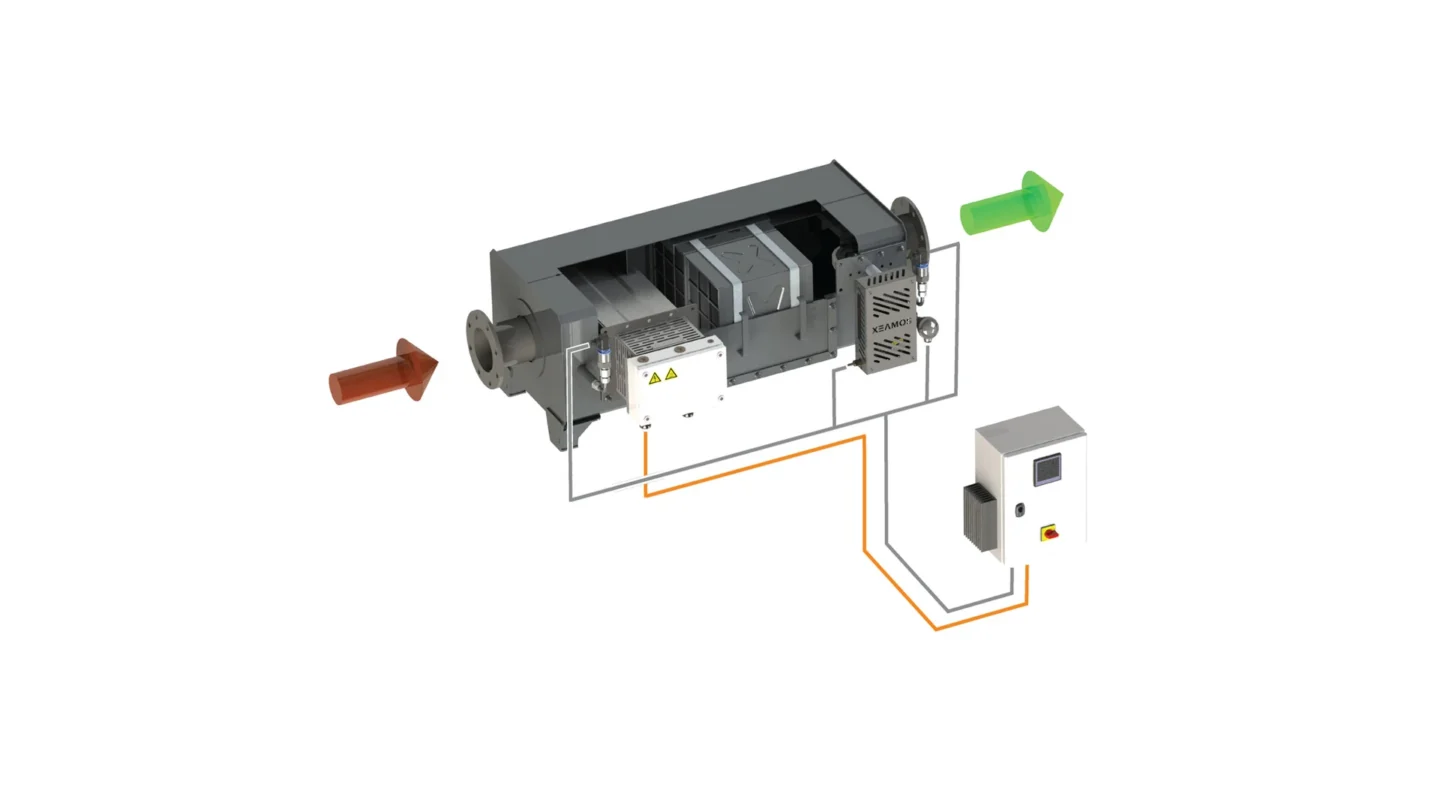

Xeamos’s Zero Soot E-heater System (ZS-EHS) is a superb example of how a treatment system can mitigate the risks posed to human health and comfort, by eliminating particulate matter measured as PM10 by >97% reduction and by converting the unburnt hydrocarbons which are responsible for the diesel odour. The system comprises a Diesel Particulate Filter (DPF) which collects the soot and ash produced by the engine, and an electrical heater designed by Xeamos that burns off the soot particles through processes called passive regeneration (when the exhaust temperature is hot enough to burn the soot unaided) and active regeneration (when the E-heater is needed to raise the exhaust temperature to soot-burning level).

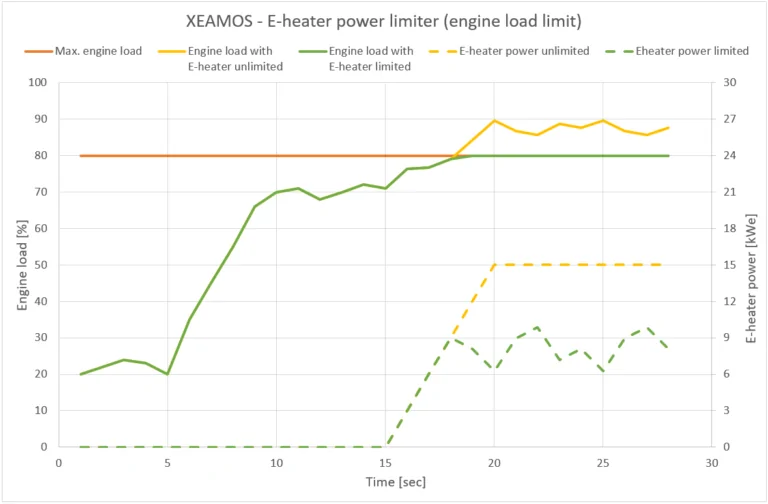

The genius of the Xeamos ZS-EHS system, and other DPFs the company produces, is not only that it can be tailor-made to a given yacht’s profile and requirements, but also that it includes intelligent design that minimises the amount of time the E-heater needs to be on, thereby reducing energy consumption, while also ensuring that power draw for active regeneration is sequenced to avoid overloading the onboard grid and causing another generator to fire up.

Alongside effective exhaust after-treatment, ongoing maintenance of the engines and generators and the choice of lubricant are the best preventative against particulate matter, as the two main sources of ash are the lubrication oil and engine wear. But most important is that the yacht’s systems are optimised to tackle not just harmful greenhouse gas emissions, but the particulate matter that is generated in the engines. It’s not just that the future health of the crew, the owner and the guests are at stake – but what could be better than tucking into an idyllic, secluded cove and being able to enjoy it just as nature intended?

Daniel van Drunen

Manager Sales

+31 (0)6 53133990